Finishing Service

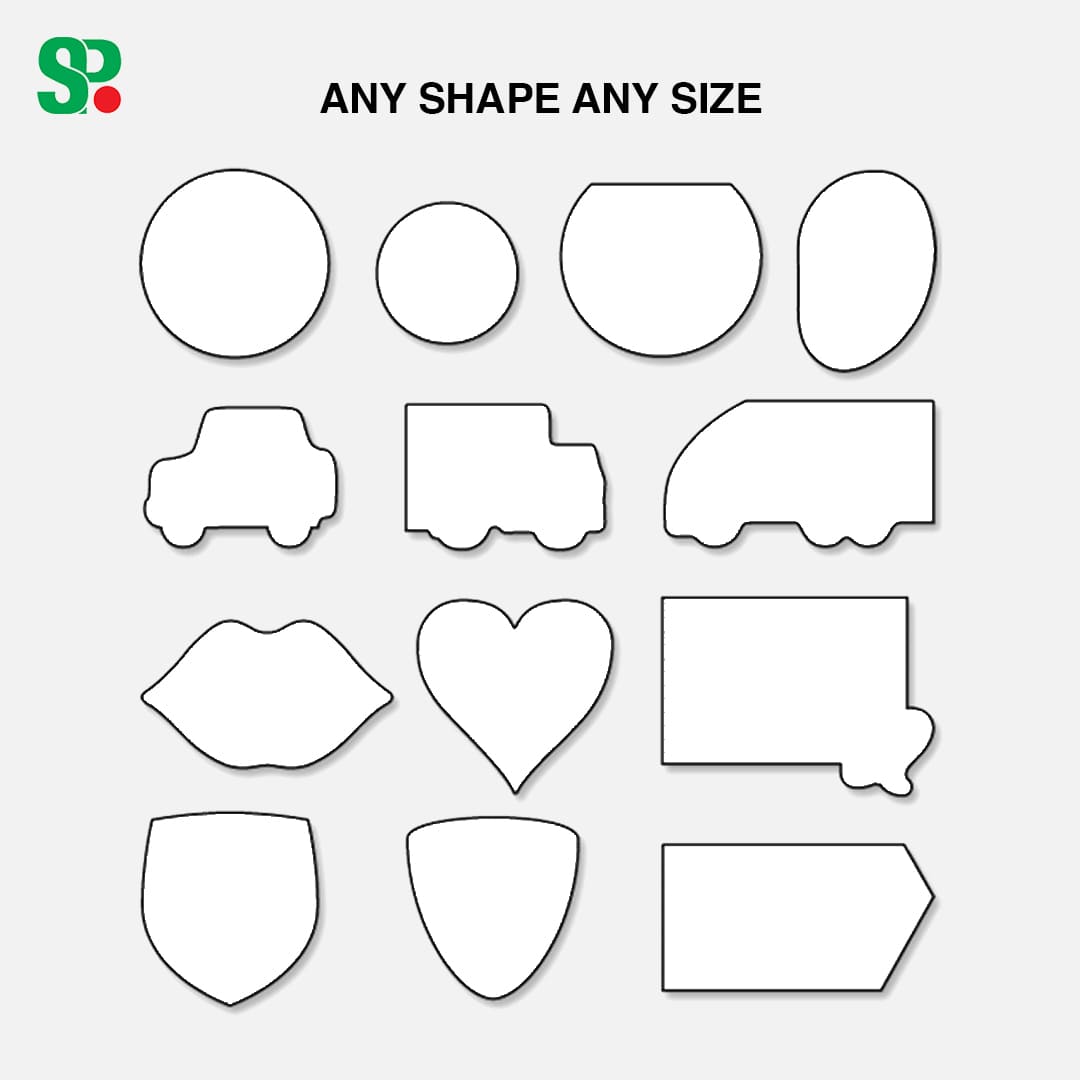

DIE-CUT (Shape as Customer Request)

Splendid Printing has various types of die-cut shapes. You may enhance your stickers with a unique shape from our various types of die-cut shapes. Die-cutting able to create customs product to helps better marketing.

ROLL FORM STICKERS

Splendid Printing can produce your labels in a roll form using any type of stock material that you require. There are 8 types of unwind direction to roll the labels. Therefore, it is important to know the unwind direction of the labels on the roll if your labels are machine applied. If you are not sure about selecting the unwind direction, just give us a call and our staffs will be able to help you.

SHEET FORM LABELS

Sheet form labels are the most economical option to choose for multiple label designs. Sheet form labels can be used either for practicality or economy.

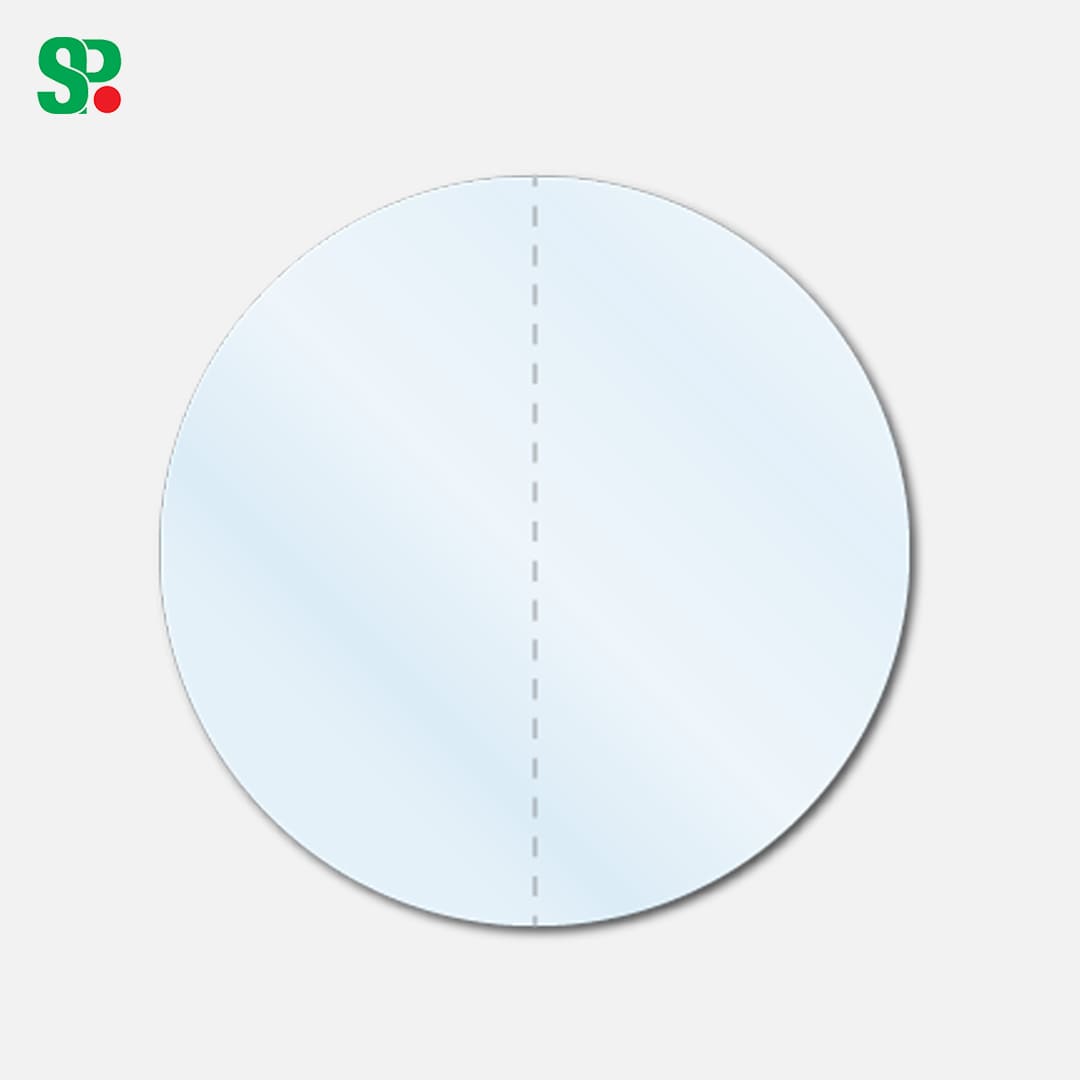

PERFORATION

Perforation is where you add a tearable portion to the paper. The size of the perforation is small and it’s separated cuts in the paper to allow pieces of paper to stay attached. It can also be torn when it’s necessary. Perforation can be custom shape or anything that needs to be perfectly torn or torn in half.

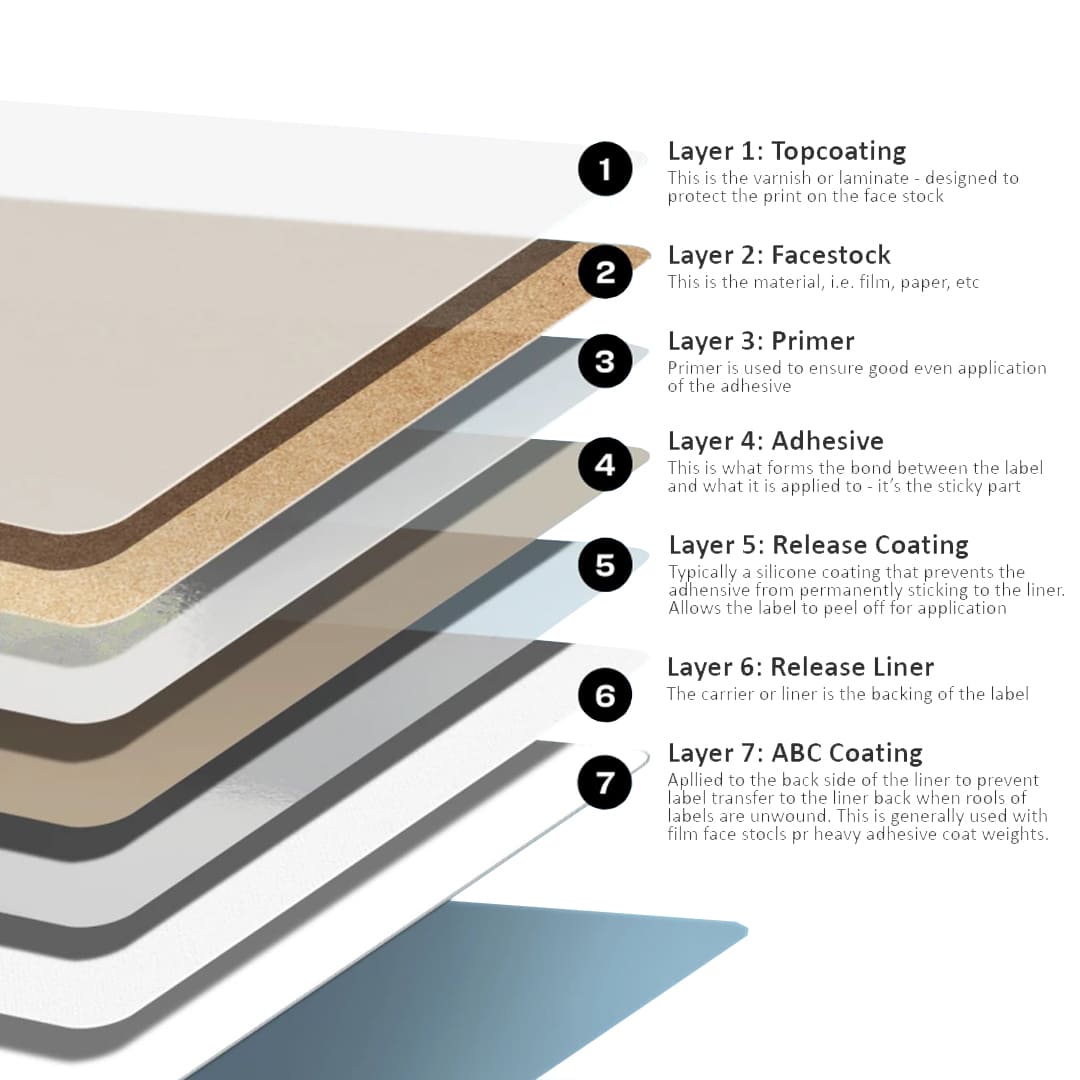

GLOSS / MATTE LAMINATION

Lamination adds a professional aesthetic and able to protect your printed materials or stickers from extensive wear with plastic film lamination.

HOT STAMPING STICKERS

Hot stamping can be used on paper, white pvc and transparent material. Hot stamping can give additional effect to your products. This sticker is frequently used for cosmetic, fashion labels or beauty items. Furthermore, adding foil stamping able to create more elegant look on your products. It also provides additional security on the products or items.

UV VARNISHING

Ultra Violet (UV) Varnishing is a process to achieve more striking and attractive type of coating on the printed material. With UV varnishing it gives your printed material looks more perfect with the varnish appearing noticeably. UV coating is like a deluxe version of non-UV varnishes which require special Ultraviolet drying machinery.

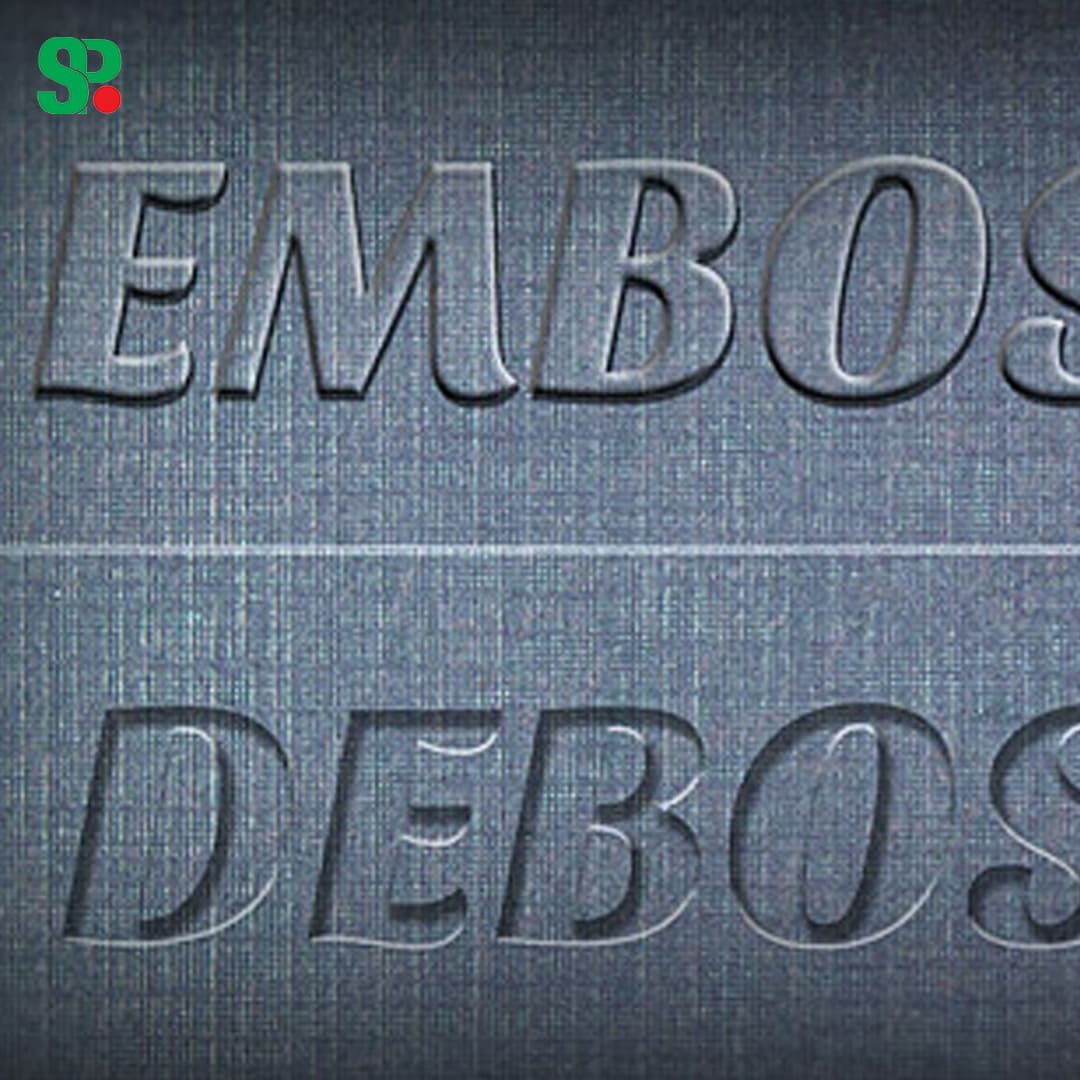

EMBOSSING & DEBOSSING

Embossing is where stamps an image or logo on the printed material, making it lift up on top of the paper surface. It creates tactile dimension on your printed material.

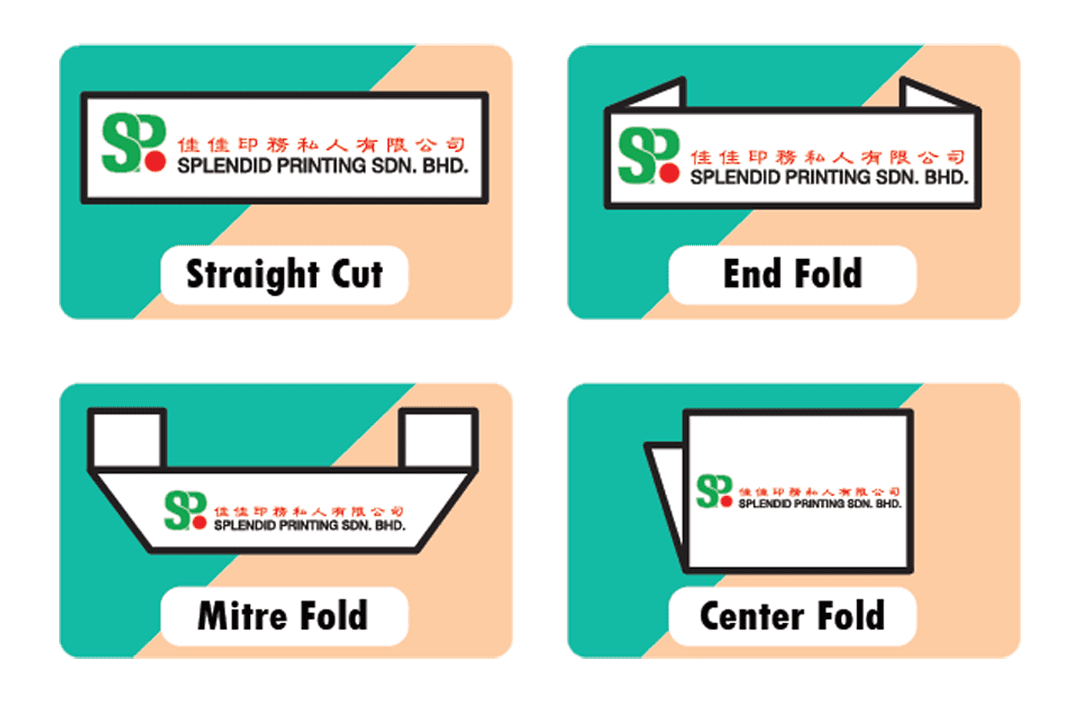

Garment Label Finishing

Straight Cut

No Folds. Straight cut labels are usually sewn on all 4 sides or 2 sides only.

End Fold

Folded down on the left and right side to create a softer edge.

Center Fold

Folded in the middle and usually sewn into a seam. Center fold labels can also be used for sleeve and hem labels.

Mitre Fold

The ends are folded under and up, creating a tab to be sewn into a seam. Additional charge for this fold.